Cracked Heat Exchangers in Furnaces: What Should We Do?

As heating season gets underway for many of us, we will inevitably find heat exchanger cracks in furnaces, whether in someone’s home or on a commercial RTU at an office building.

Many, if not all, of us have been told that a cracked heat exchanger is a hazard to people from a carbon monoxide poisoning standpoint.

But is this true?

What are the actual safety hazards of allowing a furnace to operate with a compromised heat exchanger?

Check out three cracked Carrier heat exchangers on the same roof.

This train of thought began on a recent service call.

I was asked by my boss to investigate an issue after another company had condemned a heat exchanger.

I was asked to report back the model and serial numbers so that we could give the building owners another quote for replacement.

I was also told that the other company had “repaired” the cracked heat exchanger, so I had actually to find the defect for myself.

What I found disgusted me: the other company had simply applied some RTV silicone to the opening and put it back into operation.

Before I left, I turned the natural gas and supply off because I did not want to be held liable should someone suffer, and I was the last one on site.

Unfortunately, there are not many resources when it comes to safety and cracked heat exchangers.

From a general physics standpoint, if a crack is large enough, it will disrupt the burner flame once the blower starts up.

This happens because the positive pressure of the blower fan pressurizes the heat exchanger, and the added pressure forces the flame to roll out of the burner section.

Also, we can find potential cracks via combustion analysis based on how readings change with the blower on compared to when the blower is off.

I encourage anyone who works with combustible appliances to download and read Jim Bergmann’s free guide, found at TruTech Tools’ site (https://www.trutechtools.com/Downloads), for more information on this topic.

You can also listen to Jim discuss combustion analysis on this episode of the HVAC Know It All Podcast.

I found one article written in Oct. 2004 from Contracting Business talking about CO myths (https://www.contractingbusiness.com/archive/article/20864508/carbon-monoxide-lets-stop-the-madness).

The Cracked Heat Exchanger Myth.

The main myth the author wants to dispel is that heat exchanger cracks cause CO.

This, from a scientific standpoint, is not true because the excess warm air made from the blower adds combustion air which dilutes the flue gasses.

From the experience of a number of technicians, most CO issues come from improper venting, whether it’s blocked vents, recirculation of flue gasses, or spillage due to multiple appliances sharing a common vent.

Check out Matt’s post from Instagram finding a cracked heat exchanger.

There is one notable exception when it comes to burner assemblies: gun type burners.

Most combustion appliances utilize inducer motors which pull through the furnace’s heat exchanger assembly, while gun-type gas burners, similar to standard oil burners, push through the heat exchanger.

The most notable example of these, in my experience, is Trane’s Voyager RTU line.

The heat exchangers on these have a single large header that splits into individual tubes, which is the opposite of what we typically see with “standard” burner assemblies.

In this case, the heat exchanger is actually in a positive pressure, so a crack could allow flue gasses to then be pushed into the air stream.

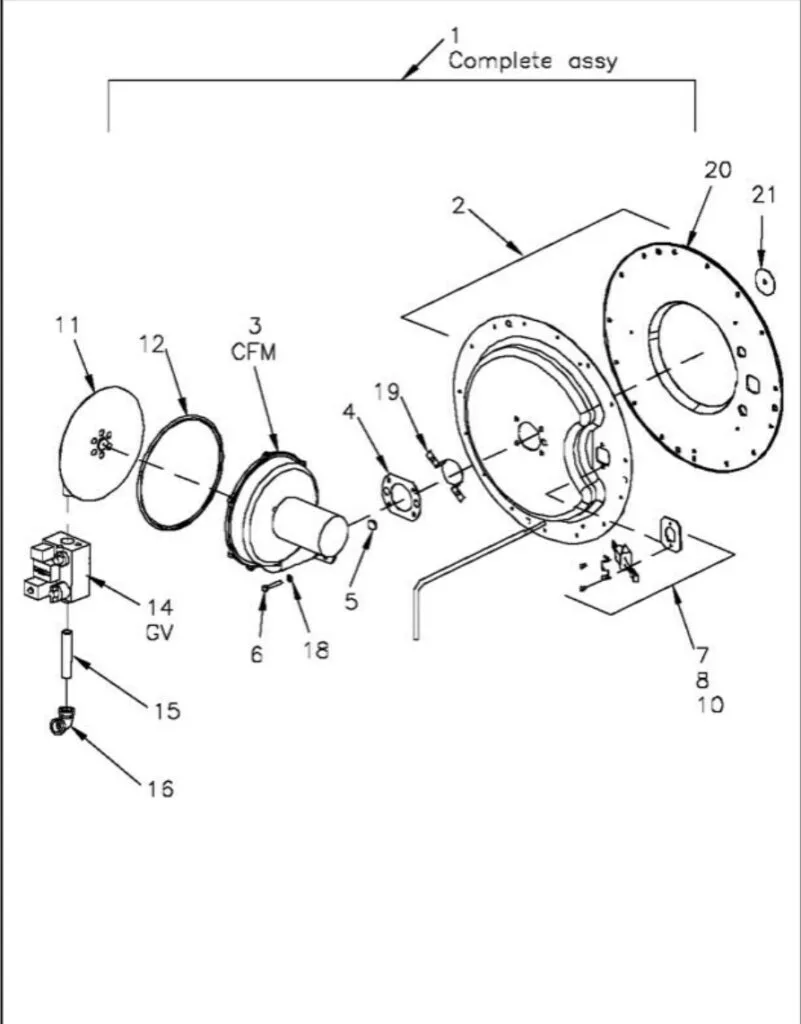

Trane Voyager burner diagram from the Trane 360 App

My Experience

Here’s a couple residential stories from my own experience: Years ago, when I was just starting in the field, I went out to a home to do heat maintenance for a new customer.

Shortly after I started my inspection, I determined there was a crack in the primary heat exchanger of the furnace, which was located in the attic.

When I talked to the customer about this, he mentioned that his two younger daughters, who were between 2 and 6, had been complaining of headaches.

This was a telltale sign of CO poisoning, as children and pets are more susceptible to its effects.

Whether this was caused by the heat exchanger or some other means, I am unsure since I was still a greenhorn.

Another time, about 2-3 years ago, I went to a person’s house who also complained of having CO symptoms.

I tested the gas furnace and found no issues there, but upon inspecting the fireplace upstairs, there was a noticeable “stain” on the metal curtain, which indicated that the chimney was blocked, causing the combustion gasses to spill into the home from just the pilot!

As technicians, we need to be aware of any and all combustion appliances, even if we are there primarily to inspect the furnace for routine maintenance.

In my opinion, any time I come across a cracked or damaged heat exchanger anywhere, I turn off the gas and in homes, I turn off the switch.

I then inform the customer about the situation and that the heat has been turned off because it poses a potential CO problem.

With commercial RTUs, I do not turn off the disconnect just in case the area warms up, and AC is then requested.

To me, this is the safest and best practice for you, your company, and the customer.

There are too many potential risks, most especially, health to the customer and liability on you.

Finally

Check out the link to my YouTube channel for more tips, tricks, and troubleshooting videos, and check out The HVAC Know It All podcast here or on your favorite podcast app.

Happy HVACing…