Obtaining reliable performance with solenoid valves on refrigeration or air conditioning systems demands careful consideration of application requirements during the selection process.

Sporlan offers a wide variety of solenoid valve sizes and styles that may be employed in refrigeration and air conditioning systems to control refrigerant flow electrically.

Solenoid valves are electrically operated ‘stop-valves.’

These are either fully open or fully closed. Remember, these do not modulate flow.

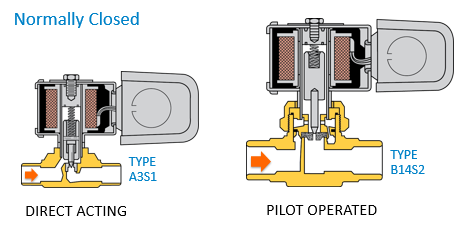

Two Basic Solenoid Valve Types:

Solenoid valves are typically classified according to the stem and plunger action.

- Direct acting – Energizing the coil directly opens the main port of the valve, allowing full flow. A direct acting valve pulls the plunger against inlet pressure and is typically limited to small applications or where there is a low-pressure differential across the valve.

- Pilot operated – Energizing the coil opens a pilot port which releases pressure above the main disc/piston/diaphragm, allowing it to move to an open position for full flow. A pilot-operated valve makes use of a pressure differential across the valve to allow for higher flow capacities without the need for a large solenoid coil. A minimum of 1 psi pressure differential is required to allow the disc/piston/diaphragm to return to its normal position. This is THE key statement, without a minimum pressure drop across the valve, once in operation, the main port will not return to normal.

Why Sizing is Important:

There has always been a tendency in the industry to select solenoid valves based on line size.

However, due to the pressure drop required for proper operation, this policy is risky and not recommended.

In other words, if a liquid line solenoid valve is being selected for a system having a 5/8 inch OD liquid line, there is a tendency to select any valve having 5/8 ODF connections.

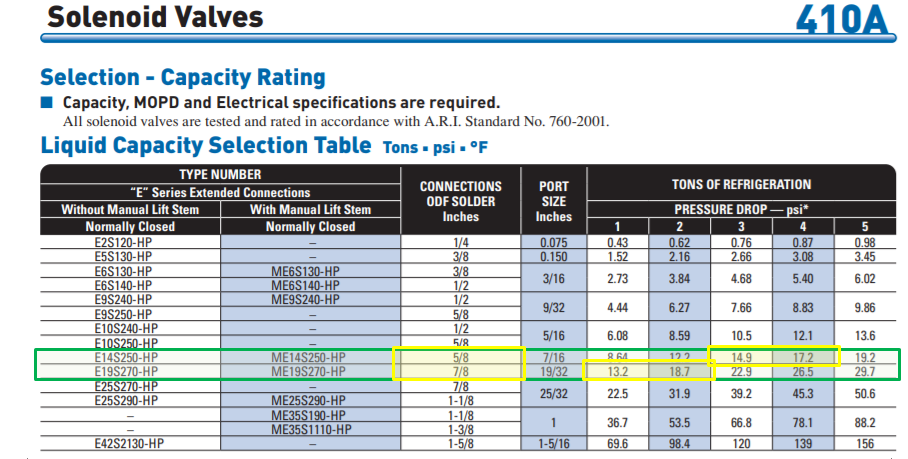

For example, we have 4 valve series with 5/8 OD connection sizes ranging from 6.0 tons to 23 tons.

If a capacity of 15 tons is required, choosing solely based on line size can lead to detrimental scenarios.

- Under-sizing and a staved evaporator.

- Grossly oversized valve, which will not have the minimum 1 psi pressure drop, and its disc/piston/diaphragm will NOT return to its normal position.

Sizing:

Choose a solenoid valve based on system capacity with a minimum of 1 psi pressure drop.

Then choose from available connection sizes.

If desired connection sizes are unavailable, bushings and couplings can be used to adapt, which will NOT affect valve performance.

Example:

15 ton, r410a, Liquid Line Solenoid valve with 5/8 OD connections:

Options:

- E14, a little over 3 psi pressure drop across the valve and has a 5/8 OD option

- E19, a little over 1 psi pressure drop across the valve, only 7/8 OD option

Sporlan 30-10: click here.

Finally

Check out the link to my YouTube channel for more tips, tricks, and troubleshooting videos, and check out The HVAC Know It All podcast here or on your favorite podcast app.